The Evolution of the BMW Engine: A Look Back at Iconic Models

Wiki Article

A Comprehensive Evaluation of Engine Efficiency Enhancements Via Advanced Fuel Injection Equipments

In the realm of vehicle design, the integration of advanced fuel injection systems has changed the landscape of engine efficiency. These innovative systems have transcended conventional gas distribution devices, using a myriad of benefits that extend past simple combustion efficiency. By thoroughly regulating the fuel-air combination and shot timing, these advanced technologies have actually unlocked a realm of opportunities for boosting engine abilities. The complex interplay in between fuel shot systems and engine performance is a topic of profound significance, losing light on the nuanced ins and outs that regulate modern propulsion. As we begin on a trip to check out the depths of these innovations, we are positioned to decipher the ins and outs that underpin the evolution of automobile giants.Evolution of Fuel Injection Technology

Throughout the history of vehicle design, the evolution of gas shot modern technology has actually been noted by significant developments in effectiveness and performance. Fuel injection systems have come a long method because their creation, with the earliest versions being mechanical and less accurate. The shift from carburetors to electronic fuel injection (EFI) systems transformed the market by offering a lot more precise fuel shipment, leading to boosted engine performance and lowered exhausts.The following major turning point in fuel injection technology was the introduction of direct gas shot (DI) systems. DI systems additionally improved engine performance by injecting gas straight into the combustion chamber at greater stress, causing much better fuel atomization and combustion. This permitted for raised power result while preserving gas effectiveness, an important equilibrium in modern-day automobile engineering.

As innovation proceeds to development, the assimilation of attributes such as gas direct shot (GDI) and stratified gas injection systems has further improved the performance and performance capabilities of modern-day engines. These improvements in fuel shot modern technology have actually played a critical duty in shaping the auto market, driving in the direction of cleaner, a lot more powerful, and fuel-efficient vehicles.

Advantages of Advanced Fuel Injection

With advancements in gas injection modern technology, contemporary engines have actually experienced considerable renovations in effectiveness and efficiency. The benefits of sophisticated gas injection systems are many. These systems give accurate control over the quantity and timing of gas delivery into the burning chamber, resulting in maximized fuel-air mix proportions. This brings about boosted fuel effectiveness, decreased discharges, and boosted power outcome. Second of all, advanced fuel injection systems add to better throttle feedback and smoother engine procedure due to their capability to provide gas extra accurately under varying driving conditions. In addition, these systems make it possible for far better cold-start efficiency, as they can readjust gas distribution based upon engine temperature level and ecological factors. Advanced fuel injection systems improve general engine dependability and long life by ensuring consistent combustion processes. On the whole, the fostering of innovative gas shot innovation uses substantial advantages in regards to efficiency, effectiveness, discharges reduction, and engine toughness, making it a crucial part in modern-day vehicle engineering.Influence on Engine Efficiency

Enhancing engine performance with the optimization of gas injection systems is an essential element of modern-day engine advancement and efficiency enhancement. The impact of sophisticated gas injection systems on engine effectiveness is substantial. By exactly regulating the amount of fuel infused into the combustion chamber and the timing of this shot, modern fuel shot systems can significantly enhance the total efficiency of the combustion procedure. This optimization leads to much more full fuel combustion, minimized gas wastage, and lower discharges result.In addition, advanced fuel shot systems can boost engine efficiency by offering much better atomization of the gas, ensuring a much more also circulation of gas droplets within the burning chamber. This boosted atomization outcomes in an extra reliable and cleaner melt, inevitably leading to greater gas performance and power outcome. Furthermore, the ability of advanced fuel shot systems to adapt to altering motoring problems in real-time additional contributes to enhancing engine performance. Overall, the effect of sophisticated gas shot systems on engine efficiency is indisputable, making them a necessary part of modern engine modern technology.

Enhanced Power Output Potential

Optimizing the power output potential of engines can be attained via calculated optimization of fuel shot systems. Advanced fuel injection systems play a critical role in improving power outcome by exactly regulating the fuel delivery to the engine. By optimizing aspects such as shot timing, gas pressure, and spray image source pattern, engineers can make improvements the burning process for enhanced power generation.One key facet of enhancing power result is making sure that the engine receives the right amount of gas at the right time. In addition, advanced fuel injection systems can allow multi-stage shot approaches, where fuel is provided in numerous pulses throughout each burning cycle.

Applications in Efficiency Design

Fuel injection systems are critical parts in performance design, facilitating specific control over fuel distribution for maximized engine operation. These systems play a crucial function in improving engine efficiency by making sure the appropriate quantity of fuel is provided at the correct time to make the most of power result, gas performance, and emissions control. In efficiency design, advanced gas shot modern technologies, such as straight injection and port fuel shot, are extensively made use of to attain certain efficiency objectives.

Furthermore, fuel shot systems are important for sustaining other performance-enhancing modern technologies, such as turbocharging and variable valve timing. By functioning in tandem with these systems, fuel shot innovation assists to maximize the general efficiency potential of contemporary engines in different applications, consisting of vehicle, visit homepage aquatic, and aerospace sectors.

Conclusion

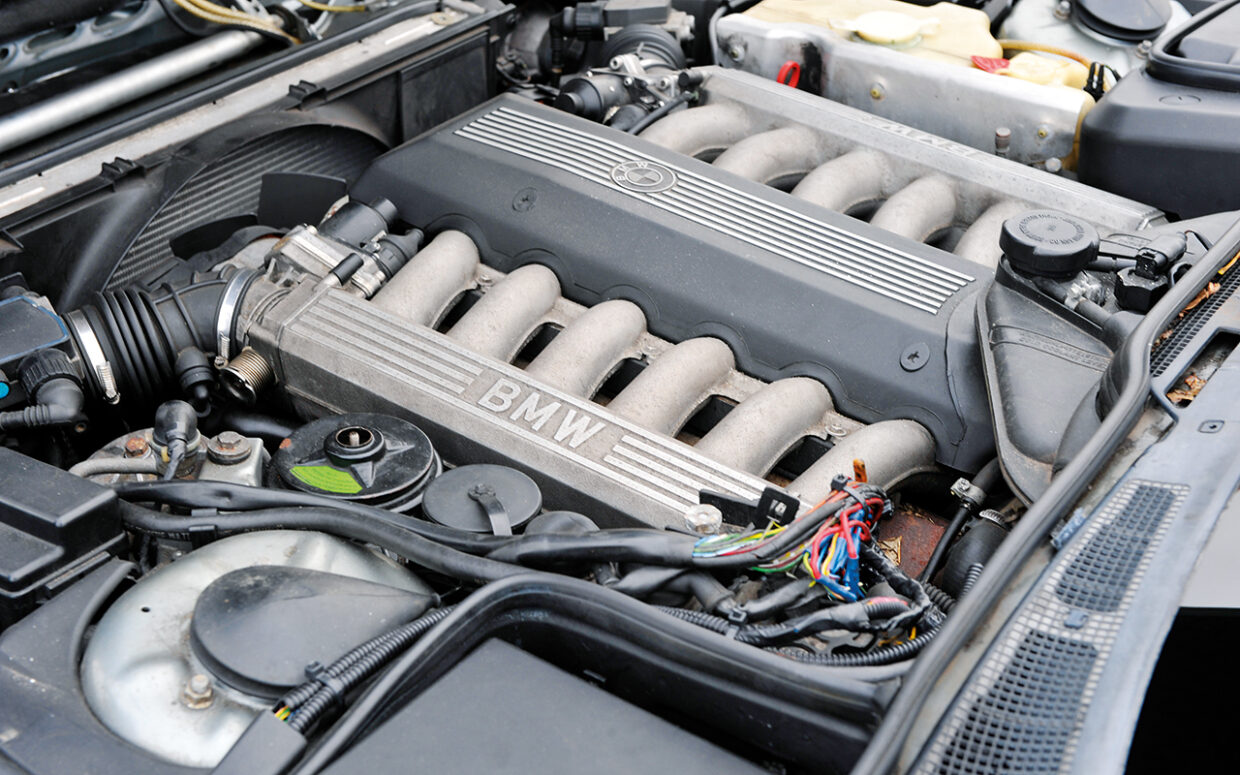

Finally, progressed gas shot systems have actually substantially enhanced engine performance by improving effectiveness and power output. The advancement of fuel injection technology has paved the way for applications in performance engineering, using a series of benefits. With these advancements, engines are able to run much more effectively, bring about boosted efficiency capacities. In general, the influence of advanced gas shot systems on engine efficiency is indisputable and remains to drive technologies in the automotive sector (bmw engine).By specifically controlling the quantity of fuel injected into the combustion chamber and the timing of injection, modern-day gas injection systems can significantly improve the general efficiency of the combustion process.In addition, progressed fuel shot systems can enhance engine performance by offering far better atomization of the gas, making certain a more also distribution of fuel beads within the combustion chamber. Furthermore, advanced gas injection systems can make it possible for multi-stage injection approaches, where gas is supplied in numerous pulses during each combustion cycle. In efficiency design, advanced fuel injection technologies, such as straight shot and port gas shot, are extensively utilized to achieve details efficiency objectives.

Report this wiki page